|

The turn of the year to 2025

brought with it some nice weather but calmer wind conditions. Donít get me

wrong, we had some blustery days, but more calmer days overall.

It was on such days that

whilst I had models to fly in light winds, I wanted something that I could still

chuck around, or something that I could possibly fly from some small sand dune type

hills and have lots of fun.

I have seen people flying

Ahiís, a great model, very manoeuvrable, but not sure thatís my bag. I wanted

something that would suit my type of flying, can groove around, but still offer

close-in aeros. I remember having a Dream flight Alula Mk1, a

tailless design, which was good, but it only came out on really calm days, I've

even got a RES model, but again, not exciting to fly and a bit fragile. So many

models are either light conditions or high wind designs, not many are out there,

as far as Iím aware, that covers both in one machine.

Given that I have quite a few

tailless designs to my CV (I like tailless designsÖ..), I set to working out

what would turn my normal design pocket rocket specification into a close-in

aerobatic wing, but one that could still take on a bit of a blustery day.

First off, was deciding on an

aerofoil section that would be suitable. I remembered that a previous DLG model

(Blaster) that I flew, had a really good speed range. It would fly slow but yet

would give a good account of itself when flown in winder conditions especially

if the aerofoil had a little reflex (speed) dialled in on the ailerons. It even

fared well on the slope.

As I didnít want a pocket

rocket, per se, I ruled out some previously aerofoils that Iíve used; MH45, PW51

etc, both very fast, no, I wanted something different to give me a wider speed

range.

Searching my Profili 2

aerofoil library I found a Mark Drela DLG wing section that seemed, visually at

least, partly reflexed. Having quickly looked at the initial data I decided to

send this to my CNC foam cutter and cut a few sample foam ribs.

Feeling that I would probably

need a little more reflex for a tailless design, I then modified the chosen

aerofoil and set an additional reflex of 1.5 degree, which looked about right.

Other considerations was that

of wing sweep. I wanted something manoeuvrable at slower speeds. Forward swept

wings seems to aerodynamically enhance roll control, much like the Dream Flight

Alula. sweep back would make the wing a little more stable and possibly faster.

The first wings was set at

40Ē span (I know, thatís old school, but then I am getting on a bit), ok then,

~1.01m. Well I was using an off-cut of foam, plus my small original Wotzat

design also has a 40Ē span, so I could directly compare this new wing to that of

the Wotzat.

The wing dimensions were

input to the CNC cutter and a set of closed cell foam cores were quickly

created, the wing tips of each panel were shaped to provide a semi elliptical

wing tip. Not only does it make it look aesthetically pleasing it also has the

advantage of reducing tip vortices and thereby, a reduction in drag.

The application of a 6mm hard

balsa root rib through which to provide a hard point for the wing bolts and 12k

carbon tows for the leading edge and Peel Ply for the living hinge. The mylars

were cut and waxed and laid up with a couple of layers of light glass cloth and

epoxy which were assembled on either side of the foam cores and put in the vac bag.

Basically a glass foam glass sandwich.

24hrs later, the panels were

taken out of the vac bag and put in the airing cupboard to keep warm for a

couple of days to continue curing before releasing the mylars from the wing.

The Reveal:

Releasing the mylars was a

pleasure. A nice finish to the wing panels, a light layup, but still quite

strong. The wings were trimmed, round servo holes cut and Elevons released

allowing the Peel Ply to operate as a living hinge.

The panels were joined with a

small amount of dihedral. The join was reinforced with my usual diamond shaped

glass cloth top and bottom. This works well to spread the load and not distract

too much from the wing profile as it can be blended to the aerofoil shape much better than glass

joining tape.

I was not in a position to

make a new lost foam fuselage but had a small balsa fuselage that could be

adapted with a tail boom to get the wing in the air quickly.

A Balsa fuselage, an 8mm uni-carbon

tube and a 3mm balsa fin joined together easily and provided a fairly attractive

fuselage. I didnít use wing bolts in the end as there was not enough of a

fuselage to install captive nuts so I improvised. A 3mm carbon rod in front of

the wing to which rubber bands could be attached, the other end of the bands

simply slid over the fin and is retained by the tail boom behind the wing. Not

pretty, but it worked!

A 300mAh NiHm battery and

small 4ch receiver and 2 high Tech HS 45 servos - its what I had in my servo box

and had been there for many years, un loved, so they now had a purpose and were

adequate for the job.

The CG was calculated for 17,

18 and 19% of the average chord. I set the cg at 18% with just a small amount of

lead up front with the AUW coming out at 279g (9.8oz) giving a wing loading of

5.8 oz/ft Sq Ė Result! But would it perform in blustery conditions???

1st Flights:

The day of the maiden flight

was a sunny day, Easterly winds, quite calm at my home but once up on the hill

the conditions a little way back from the slope edge were between 8 mph and

14mph, but at the compressive edge of the hill it was gusting to 23mph at times.

The first thing I noticed was

the model needed a little more reflex (up Elevator) to hold level flight given what seemed

like a little nose heavy. I had already set up a number of different throws for

the Elevons through use of a 3 position rate switched, so I quickly found the

right responses.

A quick and uneventful

landing saw me tweaking the CG and trailing edge reflex setting (Up trim) and it was back to the

front of the hill for another launch. This time, the launch was straight and the

model quickly picked up speed. Handling was good, the stall was almost

non-existent, even with full up elevator held in, it just went into a state of

hyper-stalls, (Gently nodding) but when released, the model quickly accelerated

putting in quite a lively performance. It needed a tweak to the Aileron

differential to make the rolls more axial, but otherwise the model seem to have

the good performance that I was hoping for.

Subsequent flights on the day

had me stretching the flight envelope to speed runs, the blustery conditions

didnít affect the model too much, it remained quite stable. Close-in, it was

performing rolls, loops stall turns way back from the edge of the slope, almost

over my head.

Subsequent days of flying the

new model did not disappoint. It worked well in light conditions but retained

its energy when flown with higher wind speed, carving turns saw the model

accelerate in the turns and half pipes providing more height than before on each

side.

Reflection:

The finish of the glass wing

was good, albeit a little fragile, already having a few dimples in the surface

from mishandling during its manufacture.

Reflecting on the first

flights I believe that I had chosen a suitable aerofoil but the trimmed position

of the elevens suggested that additional reflex was needed. A new wing was cut

with a little more reflex, now at 2 degree.

Prototype 2Ö..

The new wing panels were cut

with the additional reflex, and 88g Spread tow carbon used for the skin which

was underpinned with 49g glass cloth and a fine Kevlar hinge this time.

The wings were joined in the

same way with 10mm of dihedral under each wing tip.

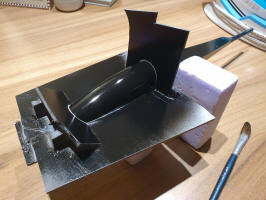

A new fuselage was then

produced using a lost foam technique. This technique requires a foam fuselage

shape to be carved and sanded, then wrapped in glass cloth and epoxy. Once

cured, the foam is removed from inside leaving what is now an epoxy glass

finish.

Installation of an 8mm uni-carbon

tube and a fin that consisted of 3mm balsa with the edges recessed and

carbon tows wrapped around its circumference. Once this was cured, I sanded

a slight symmetrical aerofoil shape feathering onto the carbon edges which was

then glassed and vac bagged with 25g cloth which provided a really nice and

strong finish.

Clearly the fuselage is

heavier than the initial balsa fuz, but this was still a development model. If I

were to mould a fuselage, I am sure I could reduce the fuz weight by at least

30%.

The whole model came out at

398g (14 oz), over 100g heavier than the first model, but it still represented a

fairly good wing loading (9.5oz/ft sq).

The maiden flight of the 2nd

model didnít disappoint. It was a winder day than previous and the model

performed extremely well. Indeed, given the extra weight, it was quick when

pushed, with it quickly gaining speed out of turns.

Feedback:

Iíve let other people fly

these two models and both said they liked its performance and showed some

interest in obtaining one of their own which was encouragingÖ. no pressure

thenÖ.. . Subsequent days out on different slopes have resulted in fellow

modellers discussing its merits behind me while Iíve been flying and plenty of

interest in the model. It does help having the spread tow carbon finish for them

to ogle and drool over Ė yes, bragging rights ÖÖ.

Given that the carbon wing is

a little heavier than the first glass version, I decided to increase the wing

span to 1.2m with a slight change in layup, still finished in spread tow carbon

but with 25g cloth underneath to reduce overall weight. The two panels came out

at just 0.8g difference and once trimmed this was further reduced to 0.4g

difference, with each panel weighing circa 86g apiece.

This new larger wing has also been

married up to the previous lost foam fuselage and its encouraging that even

though itís a larger wing, it came out at a reduced AUW of 7.5oz / ft sq.

Next time I can get out to

fly, hopefully in a few days time, the two different carbon wings and the same

fuselage will allow me to compare performance directly between the two.

Progress:

Well, time has now moved on,

with many flights taking place on different slopes with encouraging results. I

had the misfortune of a mid air collision with the new model, the other model

hitting my uni carbon tail boom. It looked as though Iíd got away with little,

if any damage. Well, that was until I pick the model up and twisted the tail.

The whole uni-carbon tail boom had split lengthways but had kept its integrity

to get model down safely.

Trying to drill out the

remnants of the uni-carbon, had me damaging the lost foam fuz, which would have

taken a lot of effort to repair. This did me a huge favour really. I didnít

spend too long coming up with a new fuselage shape fashioned out of block balsa

for the plug for a new fuselage mould.

I've made the mould so as to

use an internal bladder, essentially to inflate a balloon to push the glass and

seams into place during the cure process of each fuselage. This results in a

nicer and consistent finish inside the model. I have used this technique on both

the Wotzat and Hotshot fuselage moulds and it works well resulting in less hassle

when joining the two halves of the fuselage and a better finish.

I made the canopy mould

directly from the fuselage plug prior to laying up the actual fuselage mould.

I had also sourced some 8mm

thin walled rolled / woven carbon tube for the tail boom - more resilient and

lighter.

The new fuselage incorporates

a 3d printed internal locator for the tail boom to ensure it aligns perfectly.

The canopy shell is recessed into the fuselage. It uses a 3mm flat carbon

leading edge locator glued into the canopy shell and a small magnet to the rear

to lock it all in place.

I have now fabricated two

fuselages, one for each carbon wing set. I've even added some fluorescent paint

to the wings to make them stand out better whilst flying.

I fitted a rudder to the 1.2m

wing model which has improved its manoeuvre capability. Applying rudder during

close-in sharp

turns can really get the model turned around quickly with very little

loss in speed.

The rudder is controlled by a

single pull wire / string transiting through the tail boom to the rudder

horn. This is made possible by the use of a torque spring fitted to the hinge

line of the rudder. This puts the rudder full throw to one side, the pull from

the servo hold the rudder central, or pulls past centre to fully oppose the

spring, giving full control movement. The rudder is controlled by a

single pull wire / string transiting through the tail boom to the rudder

horn. This is made possible by the use of a torque spring fitted to the hinge

line of the rudder. This puts the rudder full throw to one side, the pull from

the servo hold the rudder central, or pulls past centre to fully oppose the

spring, giving full control movement.

I had to fit very fine brass

tubes into the fin and rudder for the 0.5mm wire torque rod to fit as the thin balsa was

being damaged by the wire. The tubes make it better and allows for the removal

of the spring if necessary. I made a 3d printed rudder servo mount for a small

7g servo that glues to the fuz side wall just inside the canopy hatch. The next

model, I will explore the use of closed loop control or even a small gauge wire

pushrod.

Both models fly well in a

good range of conditions. Indeed I have flown them in a low as 5 mph winds,

albeit I needed to work the wind / hill to keep it going and they have performed

well in wind speeds up to and in excess of 20 mph.

Ballast???

I made a 3d printed ballast

tube to fit to the 1.2m model. I have flown it with both additional 50g and 100g

brass ballast, but to be honest, it just made the model able to penetrate the higher

wind speeds, manoeuvres, were much bigger given the extra weight. but in such conditions close in aeros is probably not recommended.

I've decided that whilst ballast is an option, Iíd rather just limit the model to

flying up to circa 20mph winds, in which it performs very well with no ballast.

Thereafter, I have other models that I would want to fly in more gusty extreme

conditions.

Verdict:

Overall, I am so please with

the new model now named RAZZ (A google search says the definition of RAZZ is ďTo

Tease Ė PlayfullyĒ), which I think is an apt name for a model that evokes a

playful mode of flying.

Having now visited many different slopes and flown the

Razz, I continue to

receive some great encouraging feedback which has resulted in me making a few

Razz models for others to own and play with......

Indeed, their feedback, and I

quote is:

|