|

If you want to try your hand at Aerotowing, or have an electric model

that you want to rotate off ground rather than hand launching the model,

but don’t have undercarriage on your model, be it a scale glider or

sport glider, then building a quick and easy model Take-off Dolly is

your answer.

This one was made so that I could venture

into Aerotowing. It was used to launch my 1/5 Scale (3m) Pilatus B4.

Whilst the Pilatus has a fixed undercarriage, I didn’t want the wing

tips to drag on the ground and get damaged, especially that we were

taking-off from a Tarmac runway. The dolly kept the model well clear of

the ground and was very stable.

There are a number of photos of these types of take-off trolleys out

there on the web, but I could not find any plans; so I analysed the

photos and although I initially started to build from Plywood like may

others that I had seen, it was getting rather heavy. A bit of head

scratching and remembering Phil Morgan’s Model

stand, also featured on the Slope-dudes “ How To” pages, here is the

one I made also from plastic overflow pipe. It is neat,

lightweight and durable, the width can be changed to allow for larger

scale models and it works a treat, this also allows for it to be flat

packed.

Made from Plastic Overflow pipe and plastic fitting the finished product

was completed in just an afternoon. A quick trip to the local DIY store

should see you obtain all the bits you need, except the wheels, you'll

need to pop into your local model shop for these. I used 3" wheel - used

on Tarmac, however, I think 4" wheels would be better suited to short

grass.

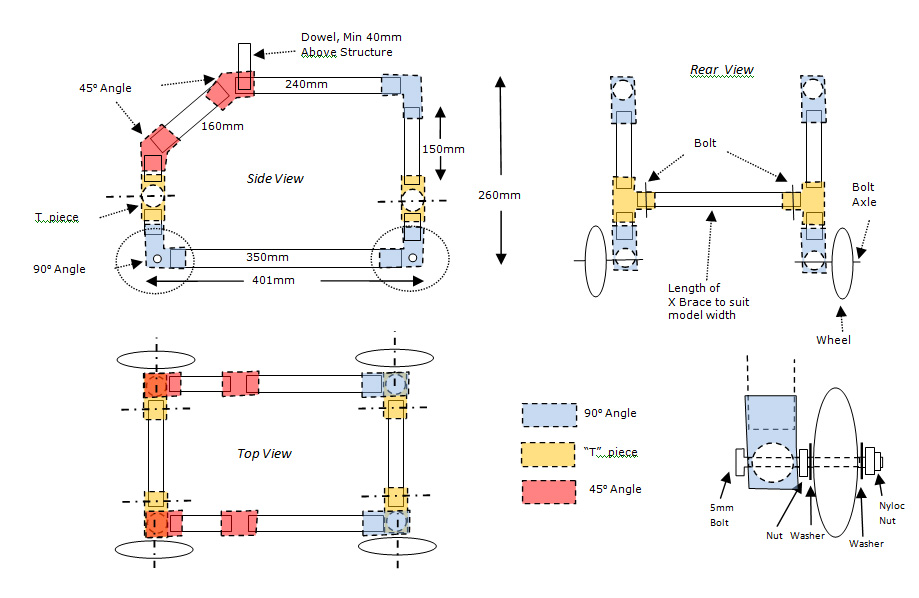

| MATERIALS |

| Length of

Plastic Pipe |

Base (2x 350mm)

Diagonal (2x 160mm)

Top (2x 240mm)

Rear (2x 150mm)

Joints (6x 30mm)

X Brace (2x 250mm (suits a 190mm width fuselage)) |

| Plastic Angles |

6 x 90° Angles

4 x 45° Angles

4 x “T” Pieces |

| Wood / Plastic Dowel |

2x Wooden Dowel / Plastic

pipe (15mm x min 50mm)

(mine are 15mm plastic doubled wall pipe with a wood dowel

inside.) |

| Wheels |

4 x Wheels (Min 80mm (3”)) |

| Bolts / Washers / Nuts |

8 x 5mm Bolts/Washes/4 x Nylock

Nuts or Optional x4 Wing nut for X Braces + 4 Normal Nuts |

| Pipe Adhesive |

|

| Pipe Lagging

(Optional) |

Thin Walled Foam Pipe

Lagging as wing seat |

The Dolly height considers the prop clearance of a few Electric models

that I have, The length is optimised to suit most of my models, although

if you wanted to drop the flaps more that s few degrees, then you would

have to take this into consideration in the length of the Top Strut.

Please note that if you change the height or length of the Dolly, due to

the front angle, all pipe lengths will change.

Each side made separately flat on bench and glued with pipe adhesive..

Make sure that the angles are correct and aligned and that the “T”

Pieces are angles correctly so that the finished dolly is Square. Glue

all joints except for the X braces.

Colin W |